The wheel is considered the most important invention of mankind. This makes long-distance travel possible and allows us to stretch long distances. To control the wheels and smooth movement, steering was implemented. Today we will show you how the steering system in a car works and how just turning the steering wheel makes the car spin.

Types of steering systems

Before going into the explanation, there are currently two main types of steering systems. The rack and pinion system is commonly used, and the common system is called the circulating ball drive system. We will also briefly explain how the power steering system works which is commonly referred to as power steering.

Rack and pinion steering

The most common steering system, the rack gear gets its name from the two gears it uses, the rack (straight gear) and the pinion (the circular gear). This system is used on most cars and is not normally used on heavy vehicles. Its working may appear complex but uses quite simple physics.

Construction of A Rack And Pinion

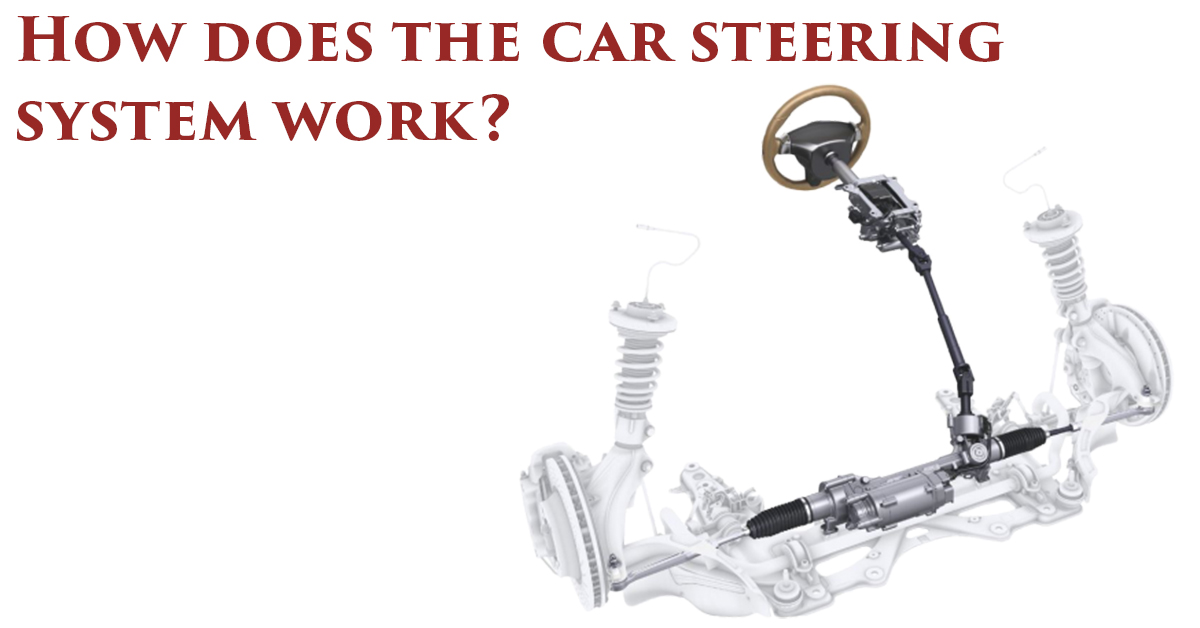

The steering wheel has a shaft attached to it and on the other end of the shaft is the pinion. The pinion is positioned on top of the rack and moves when the steering wheel is moved. The end of the rack has something called a tie rod. The tie rods connect to the steering arm which in turn is connected to the wheel hub. Let’s move on to the work of the rack and pinion.

Job

When you turn the crank, the shaft rotates with it. This in turn is the pinion on the rack. The rotation of the gear moves the rack by linearly moving the tie rod. The tie rod connects to the handlebars and then turns the wheel.

The size of the gear affects the number of turns you get. If the spur gear is large, it means you will be able to turn more revolutions with less ability to turn the steering wheel, which will make it more difficult for you to control. On the other hand, the smaller sprocket means it’ll be easier to maneuver, but you’ll need a few turns of the steering wheel to get the car into a corner.

This is how the rack and pinion system works. It is a simple device, but it can use some complex and advanced systems that can make it even better to use.

Recirculating Ball Steering System

Known by several names such as worm and zone, circulating ball and nut, this steering system is commonly found in older cars and heavy vehicles such as load. Its operation is different from the stand. Let’s take a look at the construction of a circulating ball drive system before explaining how it works.

Construction

The circulating ball drive system has two gears, a worm gear and a bow gear. The flywheel is connected to the threaded shaft which is joined as one block. The worm gear is quite large and passes through the threaded block to allow the inside of the worm gear. This block has the outer gear teeth to which the bow gear is connected. This toothed part is then connected to the pitman arm while the pitman arm is attached to the tie rod. There is a ball bearing inside the screw thread filling block. Operation is simple, as are the rack and pinion.

Operation

When the steering wheel rotates, the shaft connected to the steering wheel also rotates. The gear is bolted so it doesn’t go up and down. This rotates the block and the worm. The rotation moves the block because it’s not held by anything. The block can then move moving the toothed area, thereby moving the pitman arm. The worm gear thread is filled with ball bearings that reduce friction and prevent the gear from slipping.

This is how the circulating ball drive system works. It is rarely used now and is mostly found in trucks.

Having explained the two steering systems, we now move on to the power steering system, which is not a steering system in itself but an assist option that helps these two steering systems by reducing work that the driver must perform. do.

Power steering system

This system alone makes driving a vehicle easy. We will discuss the power steering employed by the rack and pinion steering system in brief.

The power steering adds some more parts to the rack and pinion system which makes it easier to use. Mainly the pump, pressure tubes, rotary control valve, fluid lines and a hydraulic piston.

The job of the pump is to as you might have guessed, pump the fluid around when needed. The rotary control valve ensures that the movement of fluid is only performed when the driver is actually steering the car. The hydraulic piston moves along the fluid path to deliver high-pressure fluid. This movement of the pistons on the rack makes it easy for the driver to apply most of the force needed to steer the vehicle. This section concludes the brief discussion of how hydraulic power steering works.